Electrified Cleaning -- Hangzhou Forward Gearbox

Electrically Charged Cleaning

12/17

-

2020

Inspection Environment: Temperature: 25 ℃ Humidity: 59%

Pollution Condition: Equipment is located in: gear grinding workshop, box workshop. The main pollutants are oil stains and metal dust. The equipment has been in operation for many years and has not been maintained. It is considered heavily polluted.

Quality of Completion: According to feedback from the on-site equipment personnel, the user has not performed any cleaning or maintenance on the equipment. Therefore, the equipment is severely polluted. When severely polluted, surface blowing and floor cleaning are performed. There are no effective maintenance methods for equipment in operation. After cleaning with our company's energized cleaning and maintenance products, the dust and oil stains on the surface of the equipment and inside the components are thoroughly removed. After the energized cleaning provided by our company, the equipment is obviously clean and tidy, and has advantages such as stable operation, energy saving, and consumption reduction.

Electrified Cleaning -- Shandong Chenming Paper Industry

Electrically Charged Cleaning

12/17

-

2020

Inspection Environment: Temperature: 29.8℃ Humidity: 68%RH

Pollution Condition: Equipment location: Shandong Chenming Paper Industry Group Co., Ltd., Plant 4, 1st floor paper cutting workshop. The main pollutants are oil stains and dust. The equipment has been in operation for 10 years. Routine maintenance only involves using an air blower to clean the surface of the equipment. The equipment is heavily polluted.

Quality of Completion: According to feedback from the on-site equipment personnel, the user's daily maintenance only involves using an air blower to clean the surface of the equipment, which does not achieve the optimal operating environment. Therefore, the internal pollution of the equipment is extremely serious, and there is no effective maintenance method for the equipment in operation. After cleaning with Jiangsu Duoge Electromechanical Technology Co., Ltd.'s energized cleaning and maintenance products, the dust and oil stains on the surface of the equipment and inside the components were thoroughly removed. After the energized cleaning provided by our company, the equipment is obviously clean and tidy, and operates stably with energy saving and consumption reduction advantages.

Network communication equipment - Wuxi Citizen Center dedicated line equipment

Electrically Charged Cleaning

12/17

-

2020

Device Environment: The device is well grounded and installed according to standards. The main sources of pollution are dust settled after decoration and some dust from the air.

Pollution Situation: The user's maintenance unit usually performs no maintenance on the equipment except for surface dust removal. Originally, the equipment had accumulated a lot of dust, and some equipment often experienced malfunctions. Prolonged lack of cleaning and maintenance could drastically increase the chance of downtime, severely impacting application services. The customer wants a safe and reliable cleaning service that can be performed while the equipment is powered on, without affecting its operation.

Solution: Regular maintenance service using a multi-grid network communication equipment cleaning agent. All maintenance services are performed while the equipment is powered on. The agent is non-toxic, harmless, colorless, odorless, and has a neutral pH value, preventing corrosion of equipment components, while ensuring the safe operation of the customer's equipment.

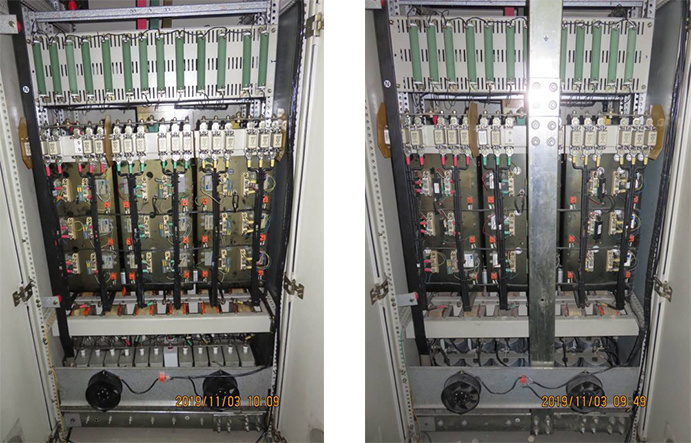

Maintenance Results: Through powered-on maintenance, dust and oil accumulated over time were effectively removed, and static electricity was eliminated. After the service, the surface temperature of the equipment dropped from 28.7℃ to 24℃. As shown in the left image, the cleanliness of the equipment has been significantly improved, greatly reducing the likelihood of safety issues.

High and low voltage switchgear - Suzhou University Affiliated Hospital

Electrically Charged Cleaning

12/17

-

2020

Equipment Environment: The substation environment is generally poor and humid, with average ventilation in the equipment room, old equipment, and unstable operation.

Pollution Situation: Due to the long-term operation of the equipment and the extremely high safety requirements for equipment in hospitals, customers are basically unable to implement power-off cleaning, and physical cleaning cannot solve the accumulation of visible pollutants.

Solution: Regular maintenance service using a multi-grid power electrical equipment cleaning agent and maintenance using a flame-retardant power electrical equipment cleaning agent.

Maintenance Effect: The before-and-after effect comparison of the equipment can be clearly seen in the pictures. The maintenance service removed more than 90% of the pollutants on the surface of the equipment and solved the problem of unstable equipment operation caused by the accumulation of dust.

High and low voltage power distribution equipment-- LiuGong Machinery Co., Ltd.

Electrically Charged Cleaning

12/17

-

2020

Equipment Environment: The equipment is located near the paint spraying, shot blasting, and polishing workshop and is in long-term contact with conductive dust, resulting in severe pollution.

Pollution Situation: There is a large amount of dust pollution on the surface of the equipment. The customer reported that there have been electrical discharge phenomena in some insulated parts of the equipment. Previously, the customer cleaned the equipment by manual cleaning with the power off, which was inefficient. The equipment downtime caused additional economic losses to the company, and only part of the surface dust was removed, resulting in no significant improvement in equipment safety.

Solution: Regular maintenance service using Duoge Electric Power electrical equipment live cleaning agent.

Maintenance Effect: The equipment operates with power during the entire cleaning process. The cleaning service thoroughly cleans the surface of the equipment, heat dissipation components, and busbar nodes. The high-speed evaporation of the liquid leaves no residue, preventing secondary dust contamination and restoring the equipment's original insulation value.

Power transmission and transformation equipment - A certain medical higher vocational school

Electrically Charged Cleaning

12/17

-

2020

Device Environment: The pre-installed substation has long-term contact with wind, sand, rain, and oil and gas.

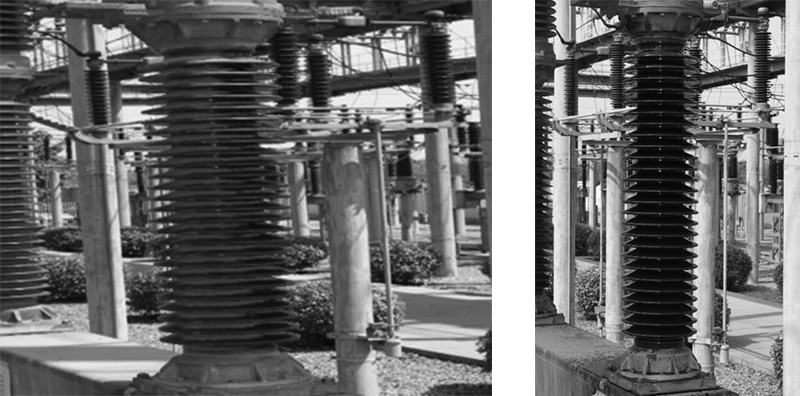

Pollution Situation: There is a large amount of dust and oil sludge pollutants on the surface of the equipment. Due to exposure to sulfides, inorganic substances, dust, and sun in the air, the equipment is severely polluted. The customer reported that the equipment had previously experienced discharge.

Solution: Regular maintenance service using Duoge Electric Power Equipment Cleaning Agent.

Maintenance Effect: The comparison of images clearly shows that the equipment is brand new after cleaning. The cleaning agent removes 90% of the pollutants through dissolving, wrapping, and carrying away, restoring more than 90% of the equipment's insulation and ensuring safe operation.